Vendor relationship management is an important area of focus for every organization, which is why companies invest in efficient procure to pay software solutions to improve supplier relationships. If managed correctly, vendors can have a significant positive impact on company growth.

Vendors provide materials, machinery, expertise, and services, amongst other things that can reduce costs, boost efficiency and improve quality. However, vendors can equally cause many problems in the form of bottlenecks, delays, and extra costs if not managed appropriately.

Strained relations within the supply chain are usually caused by a mixture of poor visibility, cooperation, and frustration, from both the vendor and buyer. It is therefore extremely important that supply chain managers assess the risks involved prior to contracting out business. Compliance needs to be positioned at the forefront of your vendor relationship strategy so that the procurement team has the right tools with which to work.

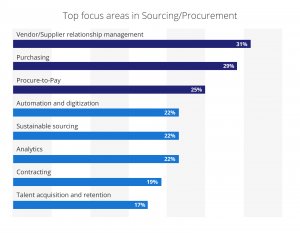

The graph below by Levvel Research displays how highly vendor relationship management professionals rank vendor validation, risk reduction, and supplier compliance amongst their most important vendor management goals.

There are three key steps that all supply chain managers should take in order to achieve vendor compliance at all stages of the vendor relationship management process.

Three-step vendor compliance process

Assess Vendor Capabilities

The fundamental question to be asked when assessing potential vendor capabilities is if they can continually maintain a high quality of service. Ensuring that your own company’s standards are not compromised is essential.

From this overarching question, specific information should be gathered regarding pricing, experience, capacity to deal with orders, and financial stability. If any of these are lacking, vendor compliance is likely to be affected at some stage.

Pre-qualification questionnaires should be used to assess potential vendor capabilities. These questionnaires are tailored to gather information specific to the goods supplied or the services provided, rather than using a generic approach.

Finally, any vendors that have been deemed viable options and subsequently fully authorized should then be used by all departments within your organization. Sometimes other departments may choose to use non-approved vendors for a simple reason such as them being cheaper. However, the risks associated with using a non-approved vendor may prove costly in the end.

Manage Vendor Contracts

It is important to maintain strong and regular communication with each of your vendors after entering into a contract with them. By keeping them up to date on strategies and plans, vendors will be able to assess how they fit in and how they can add further value.

Relationship management of this nature should act to improve vendor compliance, without you having to carry out checks.

However, it is also very important to set clear rules and policies with vendors from the outset. Vendors need to understand exactly what is expected of them and what actions could cause them to be ‘non-compliant’.

Organizations should look to formalize requirements through the creation of official contracts that vendors are bound to. Details need to be recorded and measured to safeguard against the possibility of vendors not completing their required duties in a timely manner.

Vendor contracts should also include controls and restraints to ensure they carry out expected work and don’t abuse their position within the supply chain.

Monitor Vendors

A positive start has been made to an organization’s relationship management with a particular vendor if a thorough assessment has been carried out and a clear and detailed contract of agreement has been put in place. However, in order to ensure vendor compliance for a sustained period, steps must be taken to monitor vendors regularly.

Vendor compliance management needs to include spot checks to show suppliers that you have both a knowledge of, and interest in what they do. These should prevent vendors from being lulled into a state of complacency and remind them of exactly what they are responsible for.

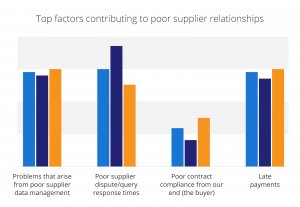

As well as conducting spot checks, carry out official audits. Key performance indicators should be used to measure the strength of all vendor relationships and performance. In a recent Levvel Research survey, 29% of organizations listed poor vendor data management as a contributing factor to poor vendor relationships.

Metrics need to be gathered, measured, and analysed to assess whether or not the desired outcomes and objectives were achieved. This process can be made a lot easier and informative by leveraging technology that will automatically track these stats.

Procure-to-Pay or P2P automation and SCM (Supply Chain Management) technologies provide access to a portfolio of vendors segmented by the likes of type, risk level, and region. Many platforms can even add automation and transparency in areas such as data management, PO and invoice tracking, for both the vendor and contractor. These improvements will all contribute to enhance vendor relationship management.

Conclusion

Vendor relationship management can be a difficult process. If you prioritize supplier compliance it will become a lot more straightforward. By strategically carrying out this three-step process and investing in technology for automation and visibility, your organization will ensure that you get the best possible service from your chosen vendors.