The procedures for a vendor onboarding process are used to protect the quality of your procure-to-pay operations and to protect your business relationships with your vendors. You should carefully develop a process for vendor management that reflects your special requirements, such as guaranteed delivery times for shipments and a two-hour time limit for receiving a reply for an email message that had been sent to a vendor. The foundations for your business relationships with vendors are established during the vendor onboarding process.

Quality of your Vendor Onboarding Process

When you initiate the negotiations process for a new vendor, you should research the qualifications of the vendor and should ensure that the services from the vendor will not impair the quality of your business operations, such as with defective products or late deliveries. Following the selection of a vendor, you should ensure that all necessary measures are in place for them to be onboarded as efficiently as possible, allowing them to begin delivering against their set goals.

There are some special techniques for establishing amicable and successful business relationships with vendors during the onboarding process.

Vendor Onboarding Strategies

Strategy 1: Develop Procedures for your Vendor Onboarding Process

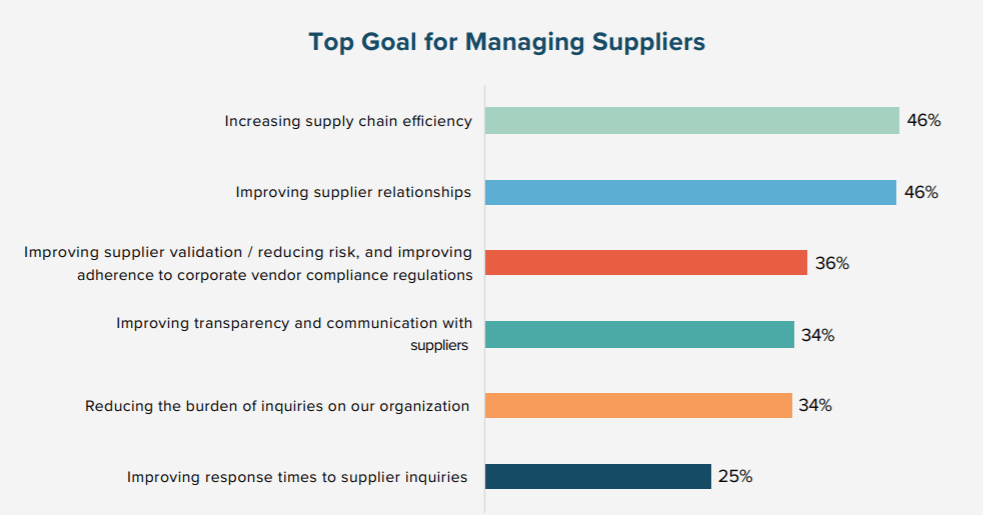

If you make a list of the problems from vendors that could quickly affect your business operations, then you could develop some methods for avoiding those problems. According to a recent report by Levvel Research, increasing supply chain efficiency and improving vendor relationships, compliance and response times rank amongst the top vendor management goals, and your vendor onboarding process should be geared towards achieving these goals.

There could be several inspections for a shipment before you make a decision about accepting the shipment. You could also require that the vendor should cover the shipping costs for late deliveries and for replacement shipments for defective goods.

Strategy 2: Develop a Process for Managing your Vendors

The professional business relationships between you and your vendors should be friendly to control social problems but should also be structured with specific procedures for helping you and the vendors to quickly resolve a problem. With detailed information about the procedures, there would be lower risk factors for problems from confusion that could cause problems for your business. Vendors should be required to review and accept such procedures during the onboarding process. In a recent blog, we talked about some of the vendor management best practices that help establish strong working relationships.

Strategy 3: Develop a Plan for Attracting Vendors with your Website

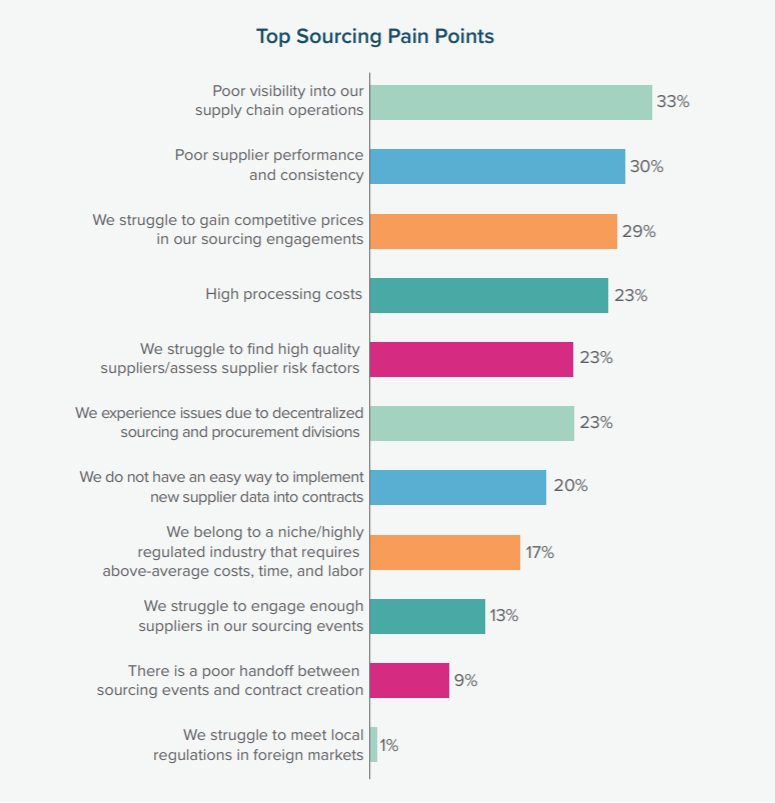

According to Levvel’s Sourcing Report, organizations seek to improve their sourcing process due to poor vendor performance, high processing costs, and a struggle to find high quality vendors.

With that in mind, you could make your sourcing and subsequent onboarding processes and lot smoother by including a web page on your website for any vendor to conveniently apply online for the opportunity to become a vendor for your company. There should be a list of the qualifications for vendors on the web page to help them assess if they are the right fit and also to layout your expectations for a smoother onboarding and management process.

Strategy 4: Develop a Communication Process for your Vendors

The comments from your vendors can be used to help you to make a decision about improving your procedures, such as procedures for ordering supplies or for submitting a payment for an invoice. With a convenient method for receiving feedback, you could be quickly informed about problems from invoices and from shipments. The vendors would have a simple process for completing a transaction if you install some special software for sharing messages with your vendors.

Strategy 5: Develop a Standard Contract for your Vendors

The contracts should include a summary page to help a vendor to save some time by quickly reading a list of the key requirements for the contract. You should also plan to meet with a vendor to discuss a contract. The vendor onboarding process should be used to help a vendor to quickly become familiar with your procedures.

Strategy 6: Assign a Level of Strategic Importance for Each Vendor

Your vendors should be evaluated during the onboarding process for a level of importance for your business operations. The importance factor should be associated with the risks for stopping your business operations, such as problems from late shipments and defective manifolds for cars, which could stop your assembly lines. The problems from vendors have different risk factors for impairing the quality of your business operations.

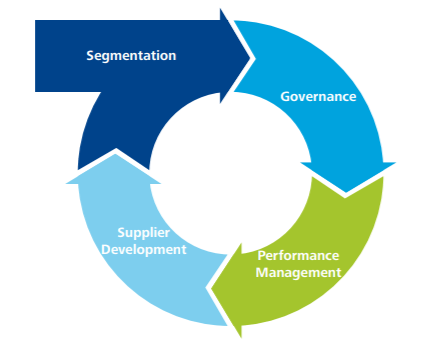

Deloitte refers to vendor relationship management as being a continuous cycle of activities that begins with segmentation.

You should segment your vendors by priority during the vendor onboarding process for better governance, performance management, and vendor development.

Strategy 7: Evaluate the Reliability and Quality Factors for Services from Vendors

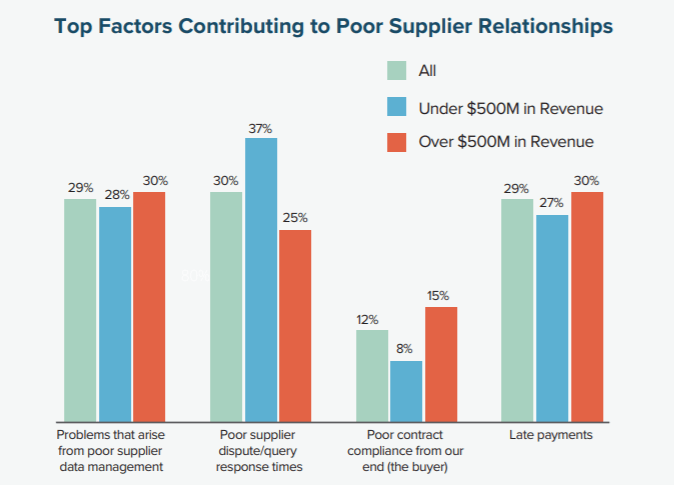

You should research information about a vendor to evaluate the reliability and quality factors for the services. The information about the financial history is an important indicator of the level of financial stability for a vendor. The professional reputation and public image of a vendor can influence the public opinion about your business. According to Levvel’s Vendor Management report, poor vendor data is one of the top factors contributing to poor vendor relationships.

The phase for researching information during the vendor onboarding process is crucial for helping your management team to decide on a vendor.

Strategy 8: Request Feedback from Several Managers for Information about Vendors

The decisions during the vendor onboarding process should be made by a management team that can evaluate the information about the financial history and the customer reviews for the services from a vendor. There is a high level of quality for the decisions from a management team because several employees can provide feedback about vendors.

Strategy 9: Management Teams for Final Decisions for the Vendor Onboarding Process

With precautions for controlling the risk factors, your management team can make a decision about a vendor. The prices from a vendor should not be the top priority for the decisions because vendors can control costs by avoiding stringent methods for inspections. You should assign one contact person for a vendor and should also organize a team of employees to help your vendors, which would give vendors several opportunities for resolving a problem.

Conclusion

A vendor can influence the quality of your business operations. With some new techniques, such as more software for messages, you could enhance your business relationships with your vendors by sending regular messages to request feedback. You should also share a welcome message about a new vendor as an announcement for your managers during the vendor onboarding process.