There are a number of ways that your organization can enhance supplier relationship management. SRM is all about interacting with suppliers and ensuring that there is a good relationship to ensure good pricing, quality products, and fast turnarounds. The goal should always be to form a win-win relationship so that both you and your supplier can benefit from the relationship.

There are also challenges with SRM. Often, they revolve around one party not understanding the culture of the other or there is a major gap in communication. Another challenge is not having any kind of transparency in the supplier’s processes.

The good news is that we are going to outline five ways for you to enhance your supplier relationship management structure and processes – and you can apply these to all of the suppliers that you work with.

Improve Processes

Unfamiliarity with a supplier’s process can create a gap. Technology will often allow you to fill this gap by facilitating more and better communication. Traditionally, your suppliers would have no insight into the progression of their invoices which causes unrest along with an increase in supplier queries.

Best-in-Class organizations are now automatically routing electronic supplier invoices to the appropriate verifiers or approvers from the moment of creation. The exclusion of paper in the process means that suppliers can be sure that documents aren’t lost or damaged while also being approved by pre-determined supervisors. Your suppliers would have access to the progress or whereabouts of any document at any given time.

This improves the transparency on your end while also reducing the stress for the supplier.

Another example of poor processes within organizations is supplier onboarding. In many organizations, supplier onboarding is a manual process with paper application forms to be filled out and laboriously routed through the organization. This leads to frustration for the supplier, the business user, and the AP team who are often left chasing the paperwork in order to process an invoice. The length of time taken often leads to delays and missed opportunities.

Educate People

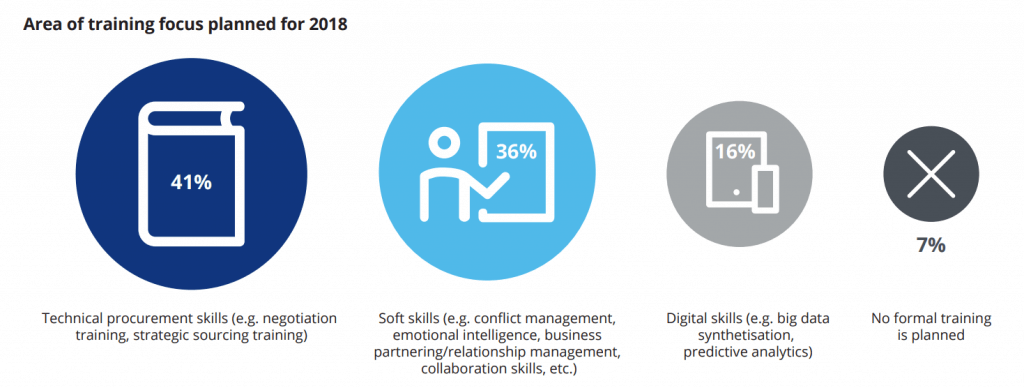

Deloitte’s recent Global Chief Procurement Officer Survey 2018 found that 51% of procurement leaders do not believe that they have the capability in their teams to deliver their strategy. This shows us that while the need for teams to develop new skills is present, there may not be a defined path for them to develop the required skill set.

Consider some of the competencies that your people have and which ones are needed to both establish and manage SRM. You will be able to enhance supplier relationship management when you take the time to work with your employees. Just as you want the relationship to be successful, so do your employees and suppliers. However, it’s not going to be a good relationship for anyone if one side is taking more than the other.

Essentially, you want to develop SRM competencies that focus on technical and relational components. You will also want to develop a training program that aligns with the SRM framework that you have created.

It may also be necessary to create a culture that focuses on quality and long-term relationships. You may currently have a culture that sees suppliers as a short-term relationship, which can be counter-productive.

Embrace Technology

There are a lot of technologies that can be used to enhance supplier relationship management. These allow you to automate a lot of the processes while also providing a higher level of transparency.

A system should allow you to have multiple components of the supplier relationship in one place. This includes:

- Supplier onboarding

- Data management

- Intuitive supplier catalog

- PO tracking

- Invoice tracking

- Supplier communication

Consider having the technology to support all of these components. You will have the ability to reduce supplier risk and also cut administrative costs that are commonly associated with managing the different suppliers that you work with. Additionally, once a supplier is onboarded updates can be made directly by the supplier. Many of the other tasks can be automated, including the internal routing of invoices.

Create a Strategy

If you don’t have a measurable strategy in place, it may be difficult to see the areas where you need to improve. There may be a lot of challenges that you can overcome simply by having a strategy in place – and that you can replicate with every supplier. For example, a core component of your strategy would be contract management.

It may also be necessary to go through some training so that you and the supplier are on the same page. This helps to bridge the culture gap and ensure that the supplier knows what you want out of the relationship at all times.

Ultimately your goal is to achieve a positive ROI and if you’re not achieving this, you need to modify your strategy.

Exhibit Governance

Strategy and governance go hand in hand. You want to throw the traditional idea of procurement out the window. Instead, let your business define what value means and use a structured approach to mapping the value.

If you’re struggling with synchronization, you also need to be more explicit with the SRM strategy and objectives. It might require some internal and external alignment.

By taking the time to conduct value mapping, you’re able to evaluate the tools, people, and processes that are in place. Further, you need to create metrics that will allow you to measure the delivery.

Conclusion

You can enhance supplier relationship management in a variety of ways. However, you have to take a step back and audit your company first. Take the time to learn where you need the most work. It could be within the technology you use or the education focus that you have. Once you know the areas that need to be addressed, you can work to build a stronger structure to support high-quality supplier relationships.