The reach of procurement within organizations is expanding. Procurement is responsible for purchasing, supplier relationship management, ensuring internal and external compliance, plus controlling costs and spend.

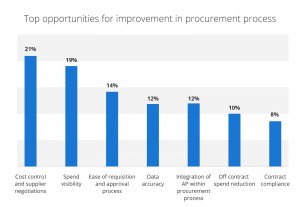

Many procurement teams are considering a procurement process redesign as they struggle with added responsibilities and face an uphill challenge to meet new demands. Traditional, manual procurement processes rely heavily on phone, email and paper-based communication for requisitions and order management. Without moving to modern procure-to-pay software, processes are time-consuming, cause errors and offer very little insight into the process. The graph below shows the areas that procurement teams see the greatest opportunity for improvement over the next 12 months.

Best in class procurement teams overcome these challenges by restructuring the way that they deal with key stakeholders such as suppliers. The key is in automating minimal, time-consuming tasks, and controlling costs.

1. Supplier Relationship Management

Procurement teams interact with suppliers on a regular basis, so it is imperative that the relationship is a strong one. While procurement teams are becoming more and more digital, they also need to digitize their most valued relationships. Manual processes for onboarding and interacting with suppliers are costly and can lead to errors further down the line.

Once procurement teams have identified their preferred suppliers, their objective should be to spend 80% of their total spend with them. Focusing on preferred suppliers allows organizations to unlock a number of benefits including pricing discounts and quicker ordering and invoicing.

Onboarding new suppliers can be done through web forms instead of paper applications where data is manually routed through the organization and entered into the ERP system. Interacting with suppliers can and should be done within a single platform where dialogue can be tracked as opposed to a chaotic fashion involving phone calls and email attachments for requisitions.

Manual processes lead to lengthy delays and missed opportunities. Updating procurement process steps can save time and remove data inaccuracies. With this said, procurement teams have to be cautious when restructuring their relationships with suppliers. The goal of increasing competition can often come at the cost of damaging the integrity of partnerships.

2. Automation of minimal, time-consuming procurement tasks

Unless you have been living under a rock for the past number of decades you’ll have noticed the impact that technology is having on our personal and business lives. The impact of technology has certainly been noticed within the procurement space, where the term ‘eProcurement’ was born.

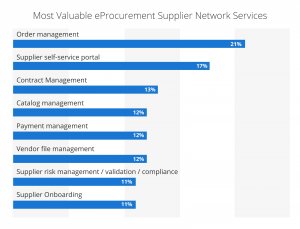

A report by Levvel Research found that 39% of companies use eProcurement solutions to place orders with suppliers. These organizations are leveraging solutions to reap a number of benefits including improved control, visibility, and profitability.

eProcurement solutions allow non-procurement staff to easily select a product or service, create a requisition, and send it for approval. The process of creating requisitions is made quicker and more efficient. Easily configurable workflows can be implemented to ensure that any spend is allocated to the correct cost center, geography, and general ledger. Approval workflows can also be configured to ensure that each requisition is approved by the correct people before a PO is created.

This post will only scratch the surface of the value that technology can add to procurement. The graph below demonstrates the variety of different areas that organizations have been able to improve because of technology and in particular, eProcurement solutions.

3. Compliant purchasing processes

When an employee creates a requisition they can often accidentally break company buying guidelines. Often unbeknownst to the employee, they may spend above their budget, send a requisition to the incorrect approver or allocate cost to the wrong cost center or general ledger.

Moving forward, it will be important for procurement teams to create a process where users are ‘guided’ through the entire buying process. Best in class organizations have systems in place where a user can choose products and services from only preferred suppliers, automatically create a requisition with the correct product details which allocate costs to the correct cost center and GL. Approval workflows can be used to ensure that the correct people approve the requisition before a PO is created.

4. Total cost management

Procurement teams are responsible for overall company spending. In traditional organizations where purchase orders are paper-based, there are no approval workflows and no cost allocation process. Visibility into the process is therefore minimal and this can be tricky.

Best-in-class procurement teams are investing heavily in procurement process redesign for improved reporting and analytics. Procurement teams that have full procurement visibility can pull real-time data on KPIs such as spend per employee, cost center, or department, as well as time to process POs. This allows procurement leaders to spot inefficiencies and find areas for improvement and development.

Non-trade spend on products and services such as stationery, electricity bills, and cleaning services are an area that can often be untracked and in turn, costly. Maverick spending means that this bracket of spend is often paid for using petty cash or credit cards. Best-in-class procurement teams find that this is an area where savings can be made. Organizations that add a formal PO process to their non-trade spend typically reduce spend by around 3%.

Conclusion

Growing demands are putting a strain on procurement teams and unfortunately, many are struggling to fulfill their requirements. More than 50% of organizations leverage technology to enhance the guided procurement process — with document imaging and scanning being the most widely used (78%) followed by automated routing and approval workflow (71%). These best-in-class organizations have left behind manual, time-consuming processes. Instead, they are now experiencing exponential benefits such as increased data accuracy, optimization of supplier base, and increased visibility into and control over spend.