Twelve months ago the outlook for procurement looked a lot different than it does today. Despite uncertainties then surrounding the upcoming US election and in Europe the eventual shape that Brexit would take, businesses could focus on efficiency and performance. But that was before Covid 19 spread across the world. Covid caused every aspect of business to be re-examined and operations recalibrated. Some of the main procurement challenges businesses faced in 2020, such as supply disruptions, hits to cash flow and the need to continue with working from home, are still with us.

We are still in the shadow of Covid with lockdowns in many countries. The lessons learned in 2020 are now even more relevant because the timing of vaccine rollouts and their effectiveness give very little reassurance. Better to assume there will be no return to business as usual. Procurement trends for 2021 are cultured by the need to recover. Businesses will need to become even more efficient and agile, in many cases just to survive and as McKinsey & Company point out, procurement can play a leading role in that recovery as it did in the aftermath of the 2008 financial crisis.

In this blog, we take a look at some of the most important trends emerging in procurement in 2021 that will help navigate further challenges in the year ahead as well boosting your procurement process both now and into the future.

Trend 1: Increased demand for digitization and automation

Remote working now characterizes the operations of many businesses. This has been a major factor in setting the agenda for automation of procurement processes. The value of fast, efficient communications and the ability of businesses to operate without the benefit of face-to-face contact has been fully understood. Procurement in 2021 will see internal procedures increasingly predicated on automation of contracts, of authorizations, reorders and stringent stock controls.

Supplier-facing automated procedures are likely to become more widely used. E-procurement catalog, requisition templates and punch-out functionalities will become the norm between businesses. These features will produce benefits such as that only preferred and properly authorized suppliers will be used across organizations. Maverick spending will be prevented and organizations will be able to leverage volume ordering to achieve best pricing and negotiate discounts. Virtually instantaneous authorization and ordering will not only add speed but also flexibility to the procurement functions of many businesses.

Trend 2: Maintaining flexibility and agility

Uncertainty in economies around the world demands that businesses can flex just about any of their functions to keep pace with rapid changes in their markets. Achieving flexibility is set to be a significant procurement trend in 2021.

Procuring closer to just-in-time will mean careful handling of supplier relationships. For example, research by EY finds that, “Specialist knowledge and expertise will be obtained by leveraging the “gig economy” on an as-needed basis.”

Global supply chains may come in for closer scrutiny where geo-political events and local conditions such as the effects of Covid and Brexit, may threaten the availability of raw materials, components and shipments. An agile approach to procurement is therefore vital. Some research highlights re-shoring and shifting to local or regional supply, bringing supplies closer to manufacturing and distribution as potential trends for 2021.

Trend 3: Cementing supplier partnerships to address supply chain risks

Against this background, a key action this year will be building strong relationships with suppliers that can live with the need for flexible sourcing and agile responses to demand shocks.

This can in some measure be achieved by the use of shared digital procurement platforms. Supply chain constraints affect both suppliers and their customers after all. Once wired into each other, buyer/supplier communications can be enhanced and early warnings of procurement blockages come to light quicker.

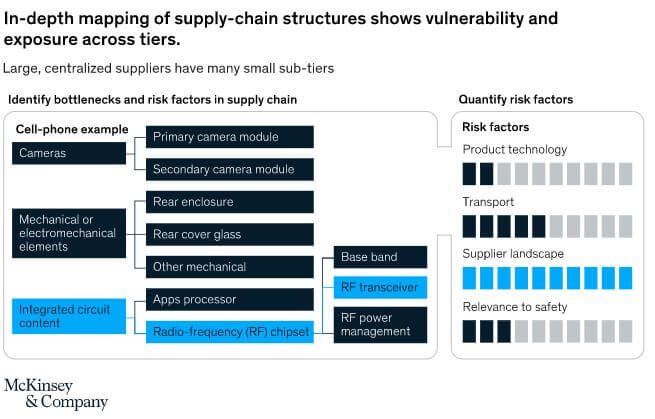

McKinsey’s research makes the point that “In the past several years, at least one company in twenty has suffered a supply-chain disruption costing at least USD100 million. Companies with complex supply-chain networks, such as automotive and technology manufacturers, are especially vulnerable.”

The consulting firm highlights the importance of thoroughly examining and understanding risks in the supply chain. Collaboration between businesses to reach into tier two and tier three supplier risk requires open exchanges of information and assessment of where risks really lie. Deciding whether supply risks are worth running is core to procuring goods and services that smoothly match a businesses’ requirement in order to ensure uninterrupted business performance.

Trend 4: Harnessing data and analytics

A key benefit of automating and digitizing supplier relationships is that they produce large amounts of data on how supply chains are actually functioning; for example, how real spend compares to budgeted projections. In 2021 data capture and analytics will become a trend unpinning procurement procedures and practice, further benefits include being able to see where spend is taking place within an organization and which suppliers receive spend in what amounts. These findings enable a broader picture of supply chain risk so that procurement teams can allocate spending to more profitable areas of a business, or among suppliers that pose less risk or may offer better delivery or payment terms.

EY draws attention to feedback loops that harness data to track and monitor procurement patterns across an enterprise. “This process will ultimately create an enhanced data platform to inform decision-making around spend and purchasing patterns, catalog content, supplier portfolios and contract fulfillment,” they say.

Moreover, data will not only be sourced from inside the enterprise. Externally sourced data will also play an important role. Although this has long been applied when, for example, assessing financial well-being of partner businesses, a broader set of research sources can help gauge product quality, supplier performance and of course macro-economic and political events and trends.

The overall impact of analyzing data on this scale is that it will provide businesses with an all-round and far-reaching view into supply-chains functioning, which will, in turn, point up the inherent challenges and opportunities they offer.

Conclusion: resilience and fight back

Together, the four main trends that we highlight here amount to businesses working hard to improve the resilience of their supply chains over the year ahead. But these trends should not simply be viewed as a reaction to Covid or a response to current uncertainties in the geopolitical landscape.

What we see happening here is the evolution of the procurement process, making it fit for the future. It is not that there’s an assumption that Covid may be here to stay or only that economies must now wrestle with challenges in a new world order which will affect customers’ behavior across the globe. Rather, the quest is for tools to do procurement better from now on. Tools such as automation, digitization, data analytics, smart contracts and catalogs, also, perhaps, the more widespread use of distributed ledger technology for greater security, will be used to help businesses respond to current and future challenges, whatever they may be. Nothing is future proof but being flexible and agile in the face of these is a sensible approach to adopt to procurement in 2021.