In an era marked by rapid change and unpredictability, the retail sector faces major supply chain challenges, with AlixPartners naming it as the industry most vulnerable to disruption in 2024. The ongoing effects of the COVID-19 pandemic, geopolitical tensions, and climate-related disruptions have all compounded retail supply chain challenges. These issues increase pressures on inventory and delivery, further strained by a global semiconductor shortage, rising material costs, and labor scarcity. Inventory challenges also impact accounts payable with slower invoice processing, approval, and payment times, contributing to overall supply chain disruptions.

Retailers must now rethink supply chain strategies, using technology to bolster resilience, enhance visibility, and maintain a competitive edge in a volatile market.

Invoice automation solutions play a key role in overcoming supply chain disruptions, bolstered by supply chain visibility tools, Artificial Intelligence (AI), and ERP integration to enhance visibility, optimize inventory, and streamline accounts payable processes. This blog explores leveraging supply chain technology to mitigate disruptions, improve competitiveness, and ensure efficiency in a dynamic market.

What are the Biggest Retail Supply Chain Challenges?

Global Disruptions

Global disruptions are significantly altering supply chain dynamics. Events like the COVID-19 pandemic and geopolitical tensions have impacted logistics and material availability, leading to increased costs and delivery delays. This is something that The Association for Supply Chain Management (ASCM) highlight in their “Top 10 Supply Chain Trends 2024” report.

Stricter border controls and rising fuel prices further complicate the flow of goods, forcing retailers to adapt by diversifying vendors and exploring new logistics strategies in order to adapt to changing conditions, minimize delays and reduce costs, while maintaining customer satisfaction amidst volatility.

Material Shortages

Material shortages challenge production and inventory levels, driven by increased demand and disrupted manufacturing. These shortages are largely the result of disrupted supply chains caused by the COVID-19 pandemic, geopolitical tensions, and extreme weather conditions. As manufacturers struggle to procure essential materials the bottleneck effects ripple throughout the retail landscape, leading to delayed production schedules and higher operational costs.

This scarcity forces retailers to reconsider purchasing strategies and vendor relationships, pushing them towards diversification and innovation in sourcing. As a consequence, customers face limited product choices and increased prices, which in turn affect brand loyalty and sales performance. Retailers are thus compelled to leverage supply chain technology and data-driven insights to forecast demand more accurately, optimize inventories, and ensure strategic planning and proactive responses, ensuring product availability and operational efficiency.

Logistical Bottlenecks

Logistical bottlenecks within the global retail industry are currently creating significant supply chain disruptions, exacerbated by the ongoing shift towards e-commerce and the demand for faster delivery times. Limited port capacities, labor shortages, and inadequate transportation infrastructure contribute to congestion, resulting in delayed shipments and increased costs for retailers.

The complexity of global trade routes, compounded by geopolitical tensions and regulatory challenges, further strains logistics networks. Retailers must look for ways to navigate these obstacles, including collaboration with logistics partners, adopting flexible distribution strategies and investing in technologies to optimize delivery operations and improve supply chain resilience.

To remain competitive and resilient in today’s unpredictable and challenging market, retailers must strategically invest in supply chain technology to prevent delays, optimize operations, and maintain a consistent flow of goods and services. Three technologies crucial to this are:

-

- Procure-to-Pay Automation

- Supply Chain Visibility Tools

- Artificial Intelligence (AI)

How Does Procure-to-Pay Automation Handle Retail Supply Chain Challenges?

Investment in automated procure-to-pay solutions is a key step to overcoming supply chain challenges. An automated end-to-end procure-to-pay solution from procurement, through to payment of vendors can help alleviate many of the retail supply chain challenges discussed already.

Having a solution in place will ensure that invoices are processed on time, vendors are paid on time and relations with vendors are maintained and enhanced.

Importance of Agile and Efficient Procurement Process

An agile and efficient procurement process is vital for maintaining supply chain efficiency in today’s dynamic market environment. By streamlining procurement activities, retailers can effectively manage vendor relationships, reduce lead times, and ensure the timely availability of goods and services. Retailers can ensure this by having eProcurement software that enables a quick purchasing process for operational spend, along with pre-approved and contract spend functionality.

Streamlining Payment Processes and Preventing Delays

Invoice automation in accounts payable is crucial for enhancing financial efficiency and preventing payment delays. Invoice automation solutions achieve this through a number of different features:

- Automation minimizes manual data entry and accelerates the approval process to ensure accurate and timely payments while enhancing cash flow.

- Automated reminders and alerts keep the team updated on upcoming due dates, which prevents late payments and eliminates associated penalties.

- Invoice automation solutions leverage AI-powered Machine Learning to:

- Identify and handle discrepancies and exceptions for rapid processing

- Enhance security and reduce operational costs

- Vendor management portals strengthen vendor relationships by offering transparency into invoice and payment statuses to support a stable supply chain and foster operational efficiency.

Improving Supply Chain Visibility and Efficiency with ERP Integration

Connecting your Enterprise Resource Planning (ERP) system with a procure-to-pay solution is essential for improving supply chain visibility and efficiency. This integration links financial operations with supply chain activities, fostering a seamless flow of information for operational efficiency.

It enables real-time tracking of inventory and production, helping retailers respond promptly to changes. Additionally, it provides insights into cash flow and working capital, aiding in financial resource management, crucial during supply chain volatility.

In summary, ERP integration is vital for resilient, efficient supply chains, enhancing transparency and strategic growth.

How Can Retailers Leverage Supply Chain Visibility Tools?

Importance of Supply Chain Visibility Tools

Visibility tools are essential for effective supply chain management, providing real-time insights. These tools help track goods from vendor to customer, ensuring transparency. By swiftly identifying disruptions, retailers can take corrective actions, maintain inventory levels, and avoid stockouts. Visibility tools enhance communication with vendors, support data-driven decision-making, and improve operations and costs. Investing in these tools is key to maintaining a competitive edge and resilience against disruptions.

Enhancing Inventory and Vendor Management

Supply chain visibility tools are revolutionizing how retailers manage their inventory amidst supply chain disruptions.

According to Accenture, leveraging data to improve visibility, is one of the top supply chain priorities that requires immediate action. Visibility tools that provide real-time insights and comprehensive tracking from vendor to consumer allow retailers to spot potential disruptions quickly and respond proactively to maintain optimal inventory levels. This transparency enhances decision-making capabilities, enabling retailers to adjust inventory practices based on precise data analytics and trends. This may mean adjusting spends vs budgets, location or vendors, depending on the circumstances.

As a result, they can significantly reduce the occurrence of stockouts or excess inventory while also optimizing spend, ensuring that consumer demand is met promptly and efficiently.

AI in Supply Chain for Demand Forecasting

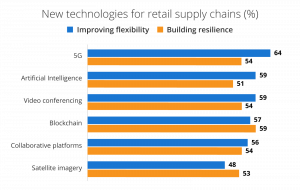

According to The Economist, as many as 59% of survey respondents named AI as improving the flexibility of their retail supply chains while 51% said the technology was helping to build resilience.

One area of the supply chain that AI is helping to improve both flexibility and resilience is demand forecasting.

Demand forecasting is a vital component of effective supply chain management, as it enables retailers to anticipate customer needs and plan inventory levels accordingly. Accurate demand forecasting reduces the risk of overstocking or stockouts, optimizing inventory costs and ensuring product availability. With the integration of AI in the supply chain, demand forecasting becomes even more powerful, leveraging data and trends to shape business strategies and ensure operation efficiency.

Predictive Analytics in Retail

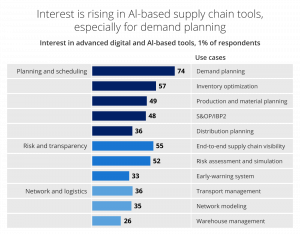

Predictive analytics is revolutionizing the retail industry by enabling retailers to more precisely forecast demand and make strategic decisions. In a recent report by McKinsey & Company, 74% of respondents named demand planning as the top supply chain area where AI-based tools were being/planning to be used.

By using AI in leveraging vast amounts of sales data and market trends, retailers can:

- Gain insights into consumer behavior,

- Identify emerging patterns, and

- Anticipate shifts in demand.

This predictive capability allows businesses to optimize stock levels, ensuring that they can meet consumer demand without overstocking or encountering stockouts and ultimately minimize waste and optimize costs. Furthermore, predictive analytics helps in refining pricing strategies and tailoring personalized marketing efforts to enhance customer engagement and loyalty. By aligning their business strategies with predicted consumer needs, retailers can maintain a competitive edge and ensure operational efficiency in today’s fast-paced market environment.

How Can SoftCo Help in Overcoming Retail Supply Chain Challenges?

Retail-Focused P2P Automation

SoftCoP2P for Retail automates the finance process from procurement to invoice automation and payment, tailored specifically for the retail sector. The solution streamlines managing complex supply chains across currencies and languages. It automates surcharge processing and enables precise budget management.

SoftCoP2P eliminates manual invoice matching and leverages Machine Learning to route and code invoices. It optimizes pricing agreements with vendors and effectively manages contract-based spending.

With SoftCo, invoice processing is 89% faster, and there’s 100% visibility and control over the procure-to-pay process, enhancing vendor relations and supply chain efficiency.

SoftCo works with leading retail brands such as Superdry, Primark, and Logitech, helping them to solve each of their supply chain challenges. For more information on optimizing your P2P process and enhancing supply chain operations, contact us today.

- TEST