The Irish manufacturing sector is navigating powerful shifts — from climate targets and global trade changes to rising costs, workforce shortages, and pressure for supply chain resilience.

AI in manufacturing is fast becoming a strategic lever to meet these challenges head-on. From traditional machine learning to new waves of generative and agentic AI, these tools are no longer theoretical — they’re becoming operational must-haves. When embedded correctly, AI isn’t just a buzzword. It enhances productivity, sharpens decision-making, and unlocks efficiencies across procurement, production, and operations.

Why Are Manufacturers Betting on AI?

In today’s unpredictable global economy, manufacturers can’t afford inefficiency. Geopolitical shifts, energy inflation, and supply volatility make lean, intelligent operations a competitive necessity.

AI offers exactly that. When deployed effectively, it improves margins, supports compliance, and streamlines complex processes like invoice matching, procurement approvals, and supplier risk evaluation.

Still, while over 40% of manufacturers are seeing measurable gains, few have reached full ROI. That’s largely due to a lack of maturity in enterprise-wide AI rollouts — an area where strategic execution makes the difference.

How AI Supercharges Operational Decision-Making

AI’s biggest gift to operations? Better decisions made faster.

By processing vast volumes of structured and unstructured data, AI allows companies to spot trends, automate responses, and course-correct in real-time. The result: fewer bottlenecks, smarter resource allocation, and faster turnaround.

Key operational wins include:

- Reduced processing times and labor costs

- Higher straight-through invoice handling

- Optimized procurement and supply chain flows

- Improved accuracy in demand forecasting

- Stronger financial control and visibility

SoftCo customers like Logitech and the Finnish Government have already realized these benefits — achieving 90% touchless processing and slashing processing costs by up to 80%.

The Roadblocks to Scalable AI

Despite the potential, many firms hit familiar friction points:

- 50% of Irish manufacturers cite data quality and IT security as top concerns

- Lack of in-house AI expertise stalls innovation

- Legacy systems create silos and slowdowns

- Compliance — especially under evolving EU regulation — adds complexity

The lesson? Implementing AI isn’t just a tech upgrade. It’s a strategic transformation that demands careful planning, workforce training, and modern platforms designed to scale securely.

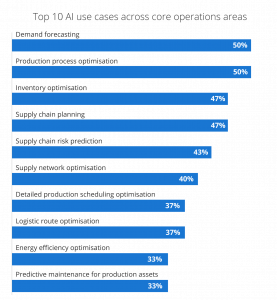

Where Is AI Having the Most Impact?

According to industry data, AI in manufacturing clusters in a few key areas:

- Supply Chain & Logistics: Forecasting, inventory optimization, supplier collaboration

- R&D and Production: Quality control, process automation, predictive maintenance

- Procurement: Spend analysis, supplier risk scoring, contract compliance

In heavily regulated sectors like pharma and med-tech, AI is already well-established across R&D and indirect procurement. By contrast, consumer goods and retail manufacturers are still in earlier adoption stages.

Four Steps to Real ROI from AI in Operations

1. Build a Business-Aligned AI Strategy

AI must serve business goals, not just tech ambitions. Identify the areas where automation and intelligence can deliver measurable value — faster approvals, lower processing costs, or improved forecasting — and align these with your strategic objectives.

Ireland’s advanced position in Europe’s tech ecosystem means manufacturers have a unique opportunity to lead here — but it starts with vision and executive buy-in.

2. Start with High-Impact Use Cases

Quick wins matter. Focus first on automation use cases that yield rapid ROI — like invoice processing, contract matching, or vendor spend control.

3. Lay the Right Data and Tech Foundation

You can’t scale AI on fragmented, manual systems. Manufacturers must unify their data and modernize infrastructure — including ERP integrations and workflow automation — to fully support AI initiatives.

At JJ Foodservice, SoftCo’s integration with Microsoft Dynamics enabled 80% straight-through processing, while three AP team members now handle 100,000+ invoices annually.

4. Create Strong AI Governance

AI implementation must be structured. That means establishing clear accountability, compliance protocols, and internal policies to ensure responsible innovation — especially in regulated industries.

This is not just about managing risk — it’s about enabling sustainable, ethical transformation.

AI Is Reshaping Manufacturing. Are You Ready?

AI in manufacturing is no longer just about futuristic use cases — it’s already improving day-to-day operations for manufacturers across Europe and beyond.

Whether you’re in early adoption or ready to scale, now is the moment to invest in systems and partners that help you move beyond pilots — and into production-level ROI.

Frequently Asked Questions

AI improves operational efficiency by automating manual tasks, accelerating invoice processing, enhancing demand forecasting, and increasing supply chain visibility. It helps manufacturers reduce costs and make faster, data-driven decisions.

Irish manufacturers face global trade shifts, cost pressures, and regulatory demands. AI offers a strategic edge by boosting resilience, reducing manual workloads, and supporting compliance in a highly competitive environment.

Common challenges include poor data quality, legacy systems, lack of internal AI expertise, and concerns about compliance with evolving EU regulations. A structured strategy and modern infrastructure are essential for success.

AI streamlines accounts payable by automating invoice matching, approvals, and exception handling. For example, SoftCo customers like JJ Foodservice achieved 80% straight-through processing with AI-enabled AP automation.

Start with a business-aligned strategy and high-impact use cases. Focus on automation opportunities with measurable ROI — such as invoice processing, supplier risk analysis, or demand forecasting — to build early momentum.