The simplest way to explain a supply chain is this: how stuff gets from there to here. Your business supply chain is like its circulatory system. The business won’t function correctly if you don’t get the supplies you need at various parts of your business. For example, if you run a fleet of delivery vehicles, you’re not going to do much business without enough diesel to run the vehicles.

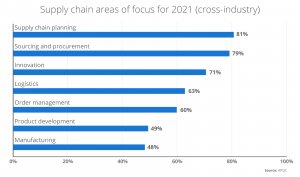

For this reason, supply chain optimization is of great importance to every organization. In a recent APQC report on priorities, supply chain planning ranked first, followed closely by sourcing and procurement.

Here are some tips on how to optimize the supply chain, improve the vendor management system, and allocate resources to produce the highest ROI.

Ways to Optimize your Supply Chain

1. Integration

The people who supply you, have people who supply them. And, those people have people who supply them, and so on. Eventually, all chains run back to raw materials, but supply chain optimization benefits all links in the chain.

Constant communication between each part of the chain improves efficiency throughout the process. To use a historical analogy, imagine how much more successful Rommel would have been if he hadn’t had to wrangle with German High Command before getting what he needed to keep the Afrika Corps running smoothly. Although he knew what was what, his chain wasn’t integrated.

Now, let’s look at a company with a fleet of delivery trucks. You will have to keep the trucks filled with fuel, maintained, and repaired when needed. For those three things, you will have three supply chains: fuel, spare parts, and tools.

To optimise the supply chain, you need to be in contact with all aspects of each supply chain. That includes the drillers, refiners, and transporters of fuel. That also includes the miners, metallurgists, machinists, transporters, and retailers for both the spare parts and the tools. Supplier Relationship Management (SRM) is an important initiative to enhance supply chain performance.

Organizations have to work closely with suppliers to secure deliveries or seek other supply sources when critical raw materials are at risk. Executive support and adequate technology are key components in boosting the organization’s attractiveness to business-critical suppliers.

Supply chain optimisation tools allow smoother interaction with suppliers, easier management of mutual obligations, and access to accurate data on business transactions and outcomes.

2. Inventory Management

Supply chain optimisation demands that businesses maintain adequate supplies, know the status of items procured, and receive timely delivery updates. During the pandemic, more companies struggled with the supply side rather than the demand — shining light on how ill-equipped companies are in maintaining adequate inventory levels in times of disruption.

Proper inventory management ensures that goods are used the way they’re supposed to be.

Let’s say that a food company with a fleet of delivery trucks delivers organic produce to both stores and individual customers.

One of the biggest advantages of managing inventory effectively is that you avoid product spoilage. No one wants to order fruit and vegetables and have them show up moldy and wilted. If you know that case of tomatoes is on loading dock No. 4 at a particular site, you can make sure it’s picked up on time.

You also have to know how much stock you need. If you can only sell 500 cases of organic tomatoes, you don’t want to pay for 600 cases because 100 cases will become dead stock instantaneously. Plus, it will spoil quickly, which wastes the time and money invested.

3. Logistics

Logistics is basically the art of hauling goods from one location to another. Goods should arrive quickly to meet customer demand. Transporting perishable items like organic produce also requires additional care to avoid spoilage.

To see how logistics is essential, let’s look at how various chains interact. You have an order of 50 tons of grapes that are to be delivered to the warehouse of a well-known supermarket. One of your delivery vehicles breaks down on the way to the warehouse, and there is a three-hour delay. Needless to say, the supermarket isn’t happy with you. Nothing spoiled, but the supermarket didn’t meet its deadline for the weekend sale that included organic produce.

The chains involved in this include:

- The supply of spare parts that could have been used to fix the truck before it broke down

- The supply of tools that should have been used by the mechanics to ensure the truck didn’t break down in the first place

- The drivers of the trucks themselves

The problem with the truck could have been as simple as a faulty intake valve. For lack of a $20 valve and about 30 minutes labor, an entire business relationship was strained. By planning ahead and providing trucks with spare parts and necessary tools, you could have avoided these headaches. Issues can also get exacerbated – 69% of companies experienced significant detriment to their logistics during the pandemic.

4. Technology

Phone calls are great, but in a business arena where minutes sometimes matter, quicker communication is necessary. When we discussed the benefits of supplier management, we highlighted how supplier management technologies are leading to increased efficiency for organizations.

A survey found that only 13.5% use specialized tools for supply chain planning and strategy. A majority of companies (57.1%) rely on spreadsheets and internal systems but one in five of these organizations are considering the purchase of specialist tools.

Depending on the size of your business, you may require a solution powered by Artificial Intelligence (AI) technology to keep track of your inventory and automate orders. If the hypothetical organic produce business has 50 trucks and a few warehouses and distribution centers, you might be able to achieve supply chain optimization with just a few PCs.

Companies the size of Amazon need entire divisions supported by the most powerful technology and secure, cloud-based management protocols and software, along with thousands of people who maintain some semblance of control over the unimaginably colossal enterprise that is their supply chain.

Even our example company needs fleet-management software, tamper-proof timecard systems, energy-efficient process flows, and communications tools to be successful at supply chain optimization.

5. Speaking of Communication…

Fortunately, this is the easiest of all to implement. You, your employees, and your suppliers just have to talk to each other. Whether that’s over the phone, in text, by email, or even video chatting, it’s the most important factor of all when it comes to supply chain optimization, especially with business-critical suppliers.

Yet, according to Deloitte’s Chief Procurement Officer Survey, only 6% of respondents claim to have full transparency of their supply chain.

This figure needs to improve if more organizations are to achieve true supply chain optimization. Without transparency and constant communication with stakeholders, you won’t get the full picture of any situation just by getting an alert.

Along with giving your employees a voice and visibility, you also need to provide training in order to enhance the ability to deliver within the supply chain. The Deloitte report looks at planned areas of training with technical procurement, such as negotiation skills and strategic sourcing, leading the way on 41%, ahead of soft skills, including relationship management and collaboration skills coming in second.

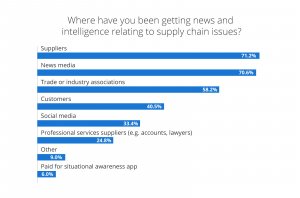

Since suppliers are the primary source of information regarding supply chain issues, maintaining constant contact is crucial for early insights into potential problems. Proactive communication is also important because not all suppliers alert customers to potential sourcing issues. When giving the opportunity, people can offer insight into better processes, and you can have discussions to determine the best course of action.

Supply chains can be extremely complex and difficult to manage at times, particularly for organizations relying on a large number of suppliers to produce different products and services.

Given additional uncertainty and risk from supply chain disruptions, investing in supply chain optimization tools like vendor management solutions improves transparency. Deploying a supply chain optimization plan unlocks business value across the chain to achieve an efficient flow of products and materials and identify enterprise-wide exposures that hamper growth.