The Covid-19 pandemic caused major disruption to supply chains and these supply chain challenges have proved persistent even after pandemic restrictions were lifted. For many organizations, this exposed a reliance, or perhaps even an over-reliance, on certain vendors while relationships with all vendors have been put to the test. As a result, a new set of vendor management best practices emerged.

Depending on the needs of your organization, you may have required discussions with vendors over minimum/maximum order quantities, payments T&Cs, or return policies, in direct response to changing consumer demands.

A lack of visibility over vendor information and activities can catch up on organizations in times of uncertainty. Areas that need addressing, such as payments T&Cs, may be difficult to identify. Once these areas have been identified, conversations with vendors are likely to be more difficult if there has been a lack of prior engagement. Failure to react quickly to supply chain disruptions can be extremely costly.

The key to handling situations like these is the prioritization of vendor management. A detailed vendor management process is not just necessary during times of disruption, but can also bring many benefits to your organization outside of a period of disruption and uncertainty.

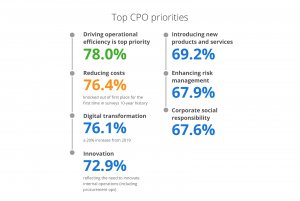

According to Deloitte, driving operational efficiencies is the top priority for Chief Procurement Officers – ranking higher than cost reduction.

Achieving efficiencies ranging from higher quality to faster delivery and competitive pricing is only possible with an effective vendor management process. This also directly impacts profitability.

Organizations that choose to prioritize vendor management strategies are in a better position to handle supply chain challenges. If you have not prioritized vendor management already or are looking at ways to implement it, the best practices listed in this blog will help you enjoy the resulting benefits.

Vendor Management Best Practices

1. Embrace Technology

Technology has changed the way businesses operate. The adoption of vendor management technology by Procurement and Accounts Payable is vital to the success of your organization.

Vendor management technology opens up a wealth of opportunities for organizations. For example, tech-supported vendor onboarding removes many of the risks associated with working with new vendors. With compliance documents and financial information uploaded from the outset and maintained thereafter, organizations have more assurances that vendors will fulfill their obligations.

A centralized system that incorporates both your vendor management and procurement processes removes the risk of maverick spending, with only approved onboarded vendors available.

Vendor management technology also brings many advantages to the AP department. By using a system that allows both Procurement to raise purchase orders and vendors to submit invoices, Accounts Payable have full visibility over the Procure-to-Pay process. Vendor portals give vendors full visibility over the status invoices that they have submitted. Any queries, delays, or discrepancies can be addressed directly with AP through the portal.

This increased visibility leads to significantly enhanced relations with vendors.

A Deloitte report revealed that a key focus for Chief Procurement Officers is supplier collaboration. During the pandemic, supplier information-sharing was the top supply mitigation strategy, making it even more important to use technology for collaboration. Unfortunately, about 52% of organizations are not using SRM tools, but many are piloting tools to enhance supplier collaboration and using them to some extent.

The key to achieving the true benefits of vendor management technology is choosing a solution that incorporates as many features as possible, benefits both your Procurement and Accounts Payable functions, and integrates well with your vendors.

2. Select the Right Partners

The vendors that you choose and your relationships with them significantly impact supply chain management and your ability to react to challenging situations.

As vendor management best practices go, selecting the right partners is vitally important and includes a number of different stages.

Firstly, it is vital to assess any potential vendors’ capabilities. Consider factors such as the capacity of their workforce, how capable they are of meeting your organization’s requirements, their location, and financial status.

Once capabilities have been assured, the details of any working relationship need to be put into a contract, stating explicitly what the vendor will provide. Details should include delivery times, order specifications, and costs, ensuring that there is clarity on both sides. Effective vendor management may allow you to re-negotiate these things during the course of the contract, but it is important to put agreements in place from the beginning of the working relationship.

However, even with contracts in place, it should not be taken for granted that vendors will always deliver the expected standards. Therefore ongoing performance monitoring should also be a key component of your vendor management.

3. Monitor Vendor Performance

Vendor performance monitoring ensures that vendors continue to provide value, adhere to contracts and agreements, and are not presenting potential risks to your business.

Central to this process will be the establishment of KPIs at the time of contract agreement with your vendors. These metrics should be clearly communicated both with your vendors and key stakeholders so that everyone knows what is expected from the relationship.

A vendor management process that monitors vendor activities, tracks compliance obligations, and maintains vendor data will ensure that you are up to date on vendor performance and can react accordingly if performance deteriorates.

4. Focus on Data and Analytics

Data and analytics are empowering organizations more than ever before to make informed, strategic decisions. This is also true in the area of vendor management, with the use of data and analytics now recognized as an area to focus on.

As reported by Deloitte, spending and saving performance analytics is one of the main areas of Procurement where technology is having a major impact.

Your Procurement activities directly impact your ability to manage your vendors. By investing in a solution that provides real-time spend analytics, you can assess your vendor risk and whether or not your dependency may outweigh the strength of the vendor.

Another benefit is identifying opportunities for savings. Such savings may be realized by re-negotiating with vendors that you have built strong relations with or by choosing not to renew contracts that offer poor value. Having detailed spend data will be key to making such informed decisions.

5. Vendor Segmentation

If your organization is the subject of a large supply chain, vendor segmentation can be one of the most effective vendor management practices. Grouping vendors, based on what they provide and how their services fit your business model, facilitates procurement activities and improves communication between your organization and your vendors. Vendor segmentation is the first step in building effective vendor relations. Categorizing vendors allows you to identify essential partners critical to business success and find a strategy tailored to enhance supplier engagement.

Some vendors may be considered strategic, while others may be essential – both segments will be handled very differently. By segmenting vendors, you provide yourself with an accurate framework in which you can truly assess their value and dedicate your efforts to them.

One of the most accurate frameworks for segmenting and assessing vendors is the Kraljic Matrix, devised by Peter Kraljic in 1983. In this, he argues that supply items should be segmented by risk and profitability.

Risk refers to the likelihood of an unexpected event occurring within the supply chain that will lead to disrupted operations. Profitability describes the impact of a supply item on the bottom line.

Given the level of disruption to supply chains since the pandemic and continued anticipated disruption, segmentation of vendors is highly recommended to minimize risk and ensure continuity.

Conclusion

Global supply chains have been severely disrupted since 2020. It is vital that organizations prepare for further disruptions with resilient and adaptable plans. Central to this plan should be a focus on vendor management. By focusing on the vendor management best practices mentioned in this blog, you will be best placed to navigate current disruptions and strengthen your supply chain for any future challenges.